2A Bergman str., Science Park, Rehovot, Israel, 7670504

Beyond 3nm

Beyond 3nm: Tackling Vibration Challenges in Advanced Semiconductor Manufacturing

How Cutting-Edge Vibration Isolation is Paving the Way for the Next Generation of Chips

The semiconductor industry is pushing the boundaries of miniaturization, racing past 5nm production nodes toward 3nm and beyond. With every technological leap, fabrication (FAB) managers and engineers face increasingly complex challenges. One often underestimated yet critical factor is environmental vibration—an invisible disruptor that can compromise precision and lead to significant financial losses in high-end chip manufacturing.

Why is Vibration a Silent Threat in Chip Manufacturing?

At the 3nm node, where transistors are mere nanometers in size, absolute precision is required in lithography, deposition, and quality control. Even the slightest mechanical disturbance can misalign nanoscale components, resulting in defective chips.

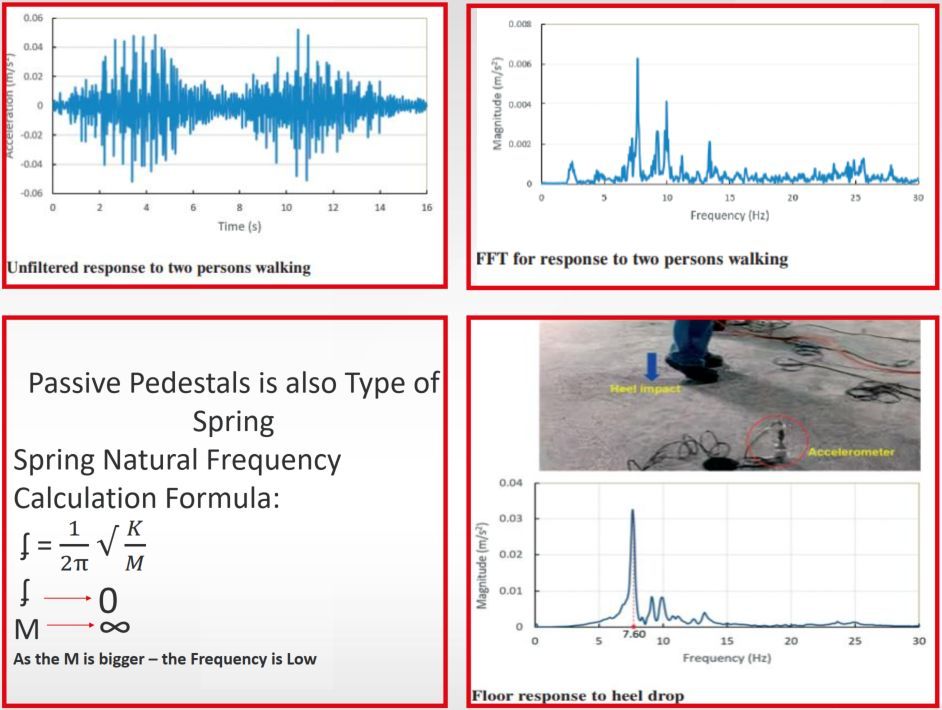

Vibrations stem from multiple sources, including:

- Equipment-Induced Movements – Industrial processes like Chemical Mechanical Planarization (CMP) and photolithography involve massive machinery that generates mechanical disturbances.

- Ambient Noise and Infrastructure Vibrations – Support systems such as HVAC units, robotic automation, and structural dynamics within multi-story fabs contribute to vibration interference.

- Personnel and Environmental Factors – Movement in cleanrooms and even external seismic activity can introduce disruptive oscillations.

The High Cost of Unchecked Vibrations

Uncontrolled vibrations can wreak havoc on semiconductor production by:

- Compromising Material Deposition and Lithography Precision – Even minute shifts can misalign layers, affecting chip topology.

- Distorting Quality Assurance (QA) Tests – Electron microscopy and other precision inspections rely on absolute stability—vibrations can lead to inaccurate assessments.

- Increasing Yield Loss and Lowering Throughput – Higher rejection rates due to vibration-induced defects reduce overall efficiency and profitability.

When the cost of producing a single 3nm chip is among the highest in the industry, vibration-related errors translate into substantial financial setbacks.

The Future of Vibration Control: Active Isolation Technology

Traditional vibration isolation methods—metal platforms, air cushions, and reinforced foundations—are no longer sufficient for ultra-low-frequency disturbances affecting nanoscale manufacturing. The new frontier is active vibration isolation, such as the ARIS MD Pro, which dynamically neutralizes disruptions in real time.

What Sets Active Isolation Systems Apart?

✔

Instant Adaptation to Disturbances – Advanced sensors continuously track vibrations, while active control mechanisms counteract disturbances before they reach critical equipment.

✔

Versatility Across Floor Types – Unlike passive solutions, these systems seamlessly integrate with modular cleanroom floors.

✔

Comprehensive Environmental Adaptability – From airborne vibrations to machine-generated tremors, active isolation solutions neutralize a wide range of disruptions.

✔

Faster Settling Times for Semiconductor Tools – Enhanced stabilization accelerates production cycles, boosting output and operational efficiency.

Is 3nm Manufacturing Viable Without Advanced Vibration Isolation?

Without cutting-edge vibration control, mass production at 3nm and beyond becomes impractical. Semiconductor fabs must prioritize yield maximization while minimizing defects—making vibration monitoring and mitigation essential for next-gen fabrication.

For manufacturing leaders, the real question is no longer if vibration isolation is necessary, but how best to implement an active system that ensures long-term technological progress.

As the semiconductor industry advances, the precision required in fabrication is reaching unprecedented levels. Environmental vibration—once considered a minor nuisance—is now a major bottleneck in achieving maximum yield and efficiency.

Implementing state-of-the-art active vibration isolation isn’t just about reducing defects; it’s about enabling the future of chip innovation. When every nanometer counts, ensuring stability is no longer a luxury—it’s a necessity.