Revolutionizing FAB Efficiency with SMU

A Smarter Approach to Vibration Management

In fast-paced semiconductor manufacturing environment, every detail plays a crucial role. Vibrations, a factor often underestimated, can have far-reaching consequences, disrupting precision processes, reducing yield, and increasing operational costs. K&S’s Smart Manufacturing Utility (SMU) emerges as an innovative response, designed to transform how FABs approach vibration monitoring, control, and optimization. This system integrates advanced technology with financial prudence, redefining standards for efficiency and precision.

Current vibration monitoring practices in FABs remain inefficient and labor-intensive. Teams are deployed to manually measure vibrations across multiple locations, generating a staggering 4,000 reports per month. Despite this effort, the data produced lacks real-time insights and actionable intelligence, resulting in missed opportunities to prevent costly downtime or enhance yields. Without a comprehensive, automated analysis process, these reports fall short of supporting proactive decision-making. Consequently, this traditional approach strains operational resources and inflates costs without delivering the precision and reliability required in high-stakes semiconductor manufacturing.

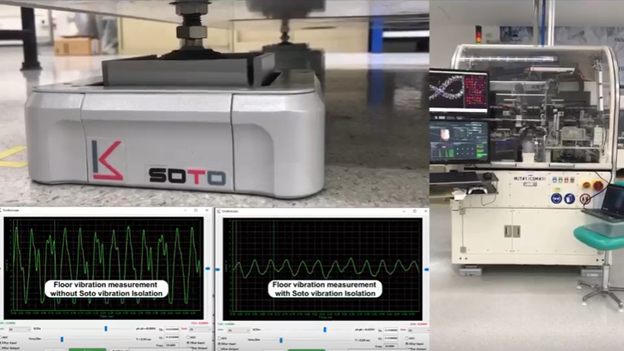

The Smart Manufacturing Utility by K&S disrupts this outdated paradigm with a technological leap forward. SMU leverages cutting-edge IoT capabilities and artificial intelligence to offer a holistic solution to vibration management. The system provides continuous real-time monitoring of vibrations in three axes—X, Y, and Z—at both the floor level and the payload of machines. Its integrated sensors precisely measure vibration amplitude and frequency, ensuring that even the most subtle disruptions are detected and analyzed. Unlike manual systems, SMU employs machine learning algorithms to interpret vibration data in real time, eliminating the need for human intervention and drastically reducing the potential for error.

The intelligent design of SMU ensures that its utility extends beyond simple monitoring. The system differentiates between sensitive and non-sensitive machines, directing active vibration control only where it is necessary. This targeted approach optimizes resource allocation and minimizes energy consumption. Sensitive machines benefit from advanced vibration control mechanisms that maintain operational accuracy and prevent performance degradation. Meanwhile, non-sensitive machines are monitored and logged, ensuring that unnecessary measures are avoided while still capturing valuable data for broader operational insights.

The integration of SMU into FAB operations is seamless and minimally disruptive. Designed for cleanroom environments and diverse laboratory settings, the system offers straightforward installation that complements existing workflows. Its user-friendly interface and robust analytics capabilities make it an indispensable tool for modern FAB management, ensuring that facilities can transition smoothly into smarter operational models.

Beyond its technological sophistication, SMU delivers substantial financial benefits that directly impact the bottom line. One of the most immediate advantages is the reduction in labor costs. By automating vibration monitoring, SMU eliminates the need for large teams of specialists, freeing up resources for higher-value tasks. Moreover, the system’s real-time monitoring and active control mechanisms prevent unscheduled downtime, ensuring that machines operate at peak efficiency. This not only reduces repair and maintenance costs but also enhances production continuity, saving significant operational expenses.

Yield optimization is another critical financial benefit of SMU. Semiconductor manufacturing relies on vibration-free environments for processes like lithography and etching, where precision is paramount. SMU creates stable conditions that enhance production quality and minimize waste, ultimately improving overall yields. Furthermore, the system’s ability to continuously monitor and adjust machine performance reduces wear and tear on equipment, extending its lifespan and delaying the need for costly replacements.

In an industry where every micron counts, SMU stands out as a strategic necessity rather than a mere operational enhancement. Its ability to integrate advanced vibration isolation with real-time analytics empowers FABs to transition from reactive problem-solving to proactive performance management. This capability not only prevents errors but also ensures optimal machine performance and yield, setting new benchmarks for efficiency and profitability.

For FAB managers, executive vice presidents, and financial departments, SMU represents the perfect convergence of innovation and practicality. It addresses the technical demands of modern manufacturing while delivering measurable financial benefits. By adopting SMU, FABs can elevate their operational standards, achieve higher levels of precision, and secure their competitive edge in a rapidly evolving industry.

The future of semiconductor manufacturing lies in smarter systems and proactive solutions. K&S’s Smart Manufacturing Utility is not just a tool for managing vibrations—it is a catalyst for transformation, enabling FABs to redefine what’s possible in efficiency and performance. The time to embrace this innovative technology is now, as the path to smarter, more profitable manufacturing has never been clearer.