Maximizing Semiconductor Manufacturing Yield with Advanced Vibration Control

Maximizing Semiconductor Manufacturing Yield with Advanced Vibration Control

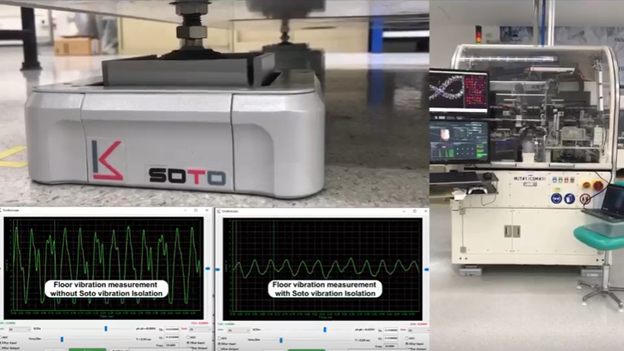

Precision is the cornerstone of semiconductor manufacturing. Processes such as photolithography, deposition, and etching demand an environment free from even the slightest disturbances. Achieving this precision is not just a technical challenge but a strategic imperative for manufacturing success.

The relationship between vibrations and production yield is clear. Uncontrolled vibrations disrupt critical processes, causing defects and significantly reducing output quality. By contrast, advanced vibration isolation systems ensure a stable environment, maintaining consistently high yields even under challenging conditions. The data speaks for itself: fabs equipped with proper vibration control systems outperform those without by a wide margin.

The Impact of Vibration on Yield

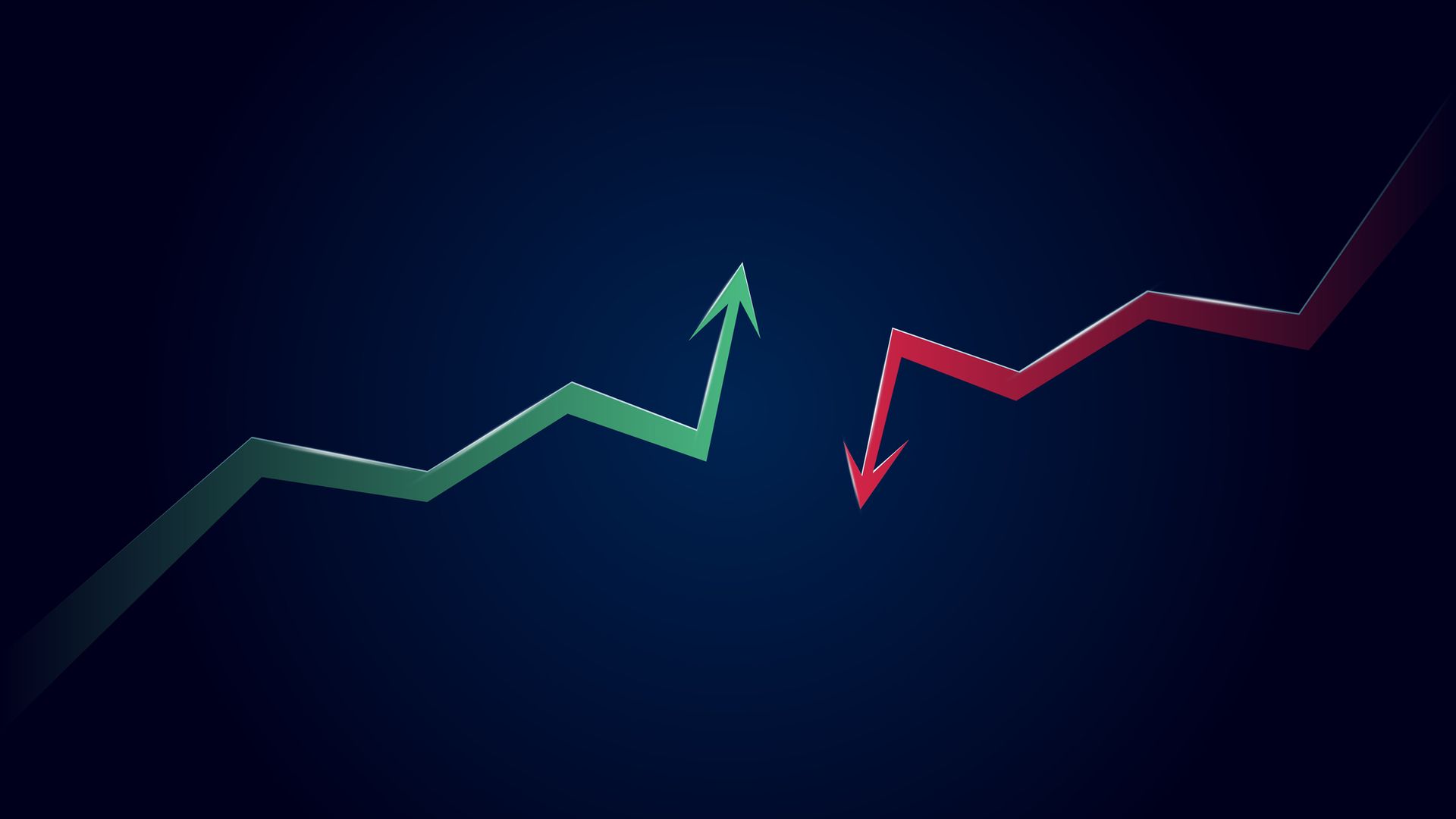

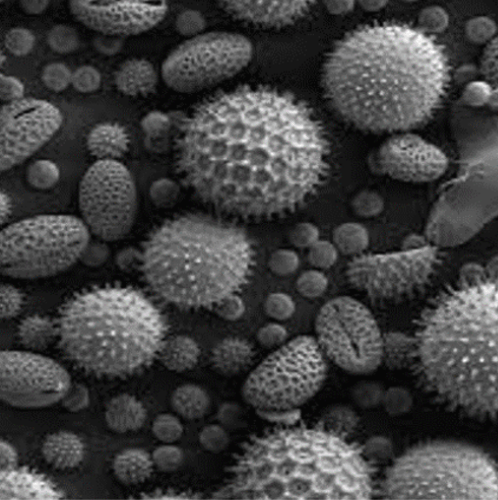

A visual comparison of manufacturing outcomes highlights the importance of vibration control. Without effective isolation, yield drops precipitously as vibration levels rise, with reductions of up to 35% at higher vibration intensities. Conversely, facilities equipped with advanced vibration isolation maintain yields above 95%, regardless of environmental disturbances. These results underline a simple truth: vibration control isn’t a luxury—it’s essential.

For decision-makers, these figures translate into tangible benefits. High yields mean fewer defects, reduced rework, and maximized operational efficiency. In an industry where every percentage point of yield matters, the decision to invest in vibration isolation systems becomes not just practical but imperative.

Why Choose KNS Advanced Vibration Control?

1. Proven Reliability KNS systems deliver measurable improvements in yield, ensuring your manufacturing operations remain competitive in an increasingly demanding market.

2. Seamless Integration Designed for compatibility with modern semiconductor facilities, these systems are straightforward to implement and require minimal adjustments to existing operations.

3. Future-Ready Design As semiconductor processes evolve, precision requirements become even stricter. KNS systems are engineered to meet the needs of today and tomorrow, supporting cutting-edge technologies and workflows.

4. Risk Reduction Beyond improving yields, effective vibration control reduces the risk of equipment wear, process interruptions, and downtime caused by environmental factors.

Make the Right Decision

Maintaining competitive advantage in semiconductor manufacturing requires more than just cutting-edge tools; it demands the infrastructure to support precision at every stage. Advanced vibration isolation systems are no longer optional; they are a cornerstone of modern fabs. With KNS Advanced Systems, manufacturers can ensure maximum yields, optimal efficiency, and the confidence to meet industry demands head-on.

Contact Us Today

Ready to unlock the full potential of your manufacturing operations? KNS Advanced Systems Ltd. is here to help you achieve unparalleled precision and productivity. Contact our team directly to schedule a consultation and explore tailored solutions for your facility.